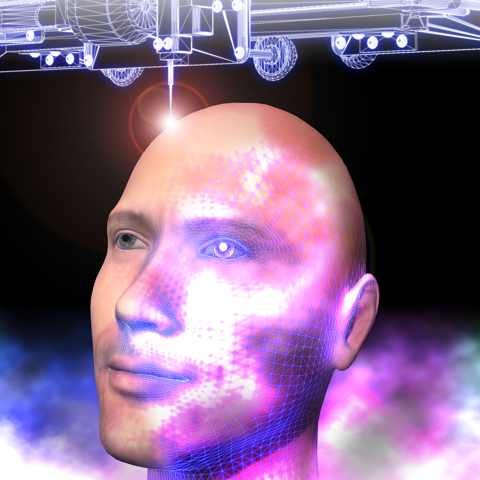

University of Bristol scientists have revealed a new Bio-Ink for 3D printing using stem cells that allows printing of living tissue called as Bio-Printing

Bio ink consists of two various Polymer Components

- A natural polymer extracted from seaweed

- A sacrificial synthetic polymer used in the medical industry

Functionality of Bio-Ink

When the temperature is raised, the bio-ink is released from a special 3D printer head on to a warm printer base where it turns to a solid gel i.e liquid to solid containing all the ingredients to form living tissue

Seaweed Polymer provides Structural support when the cell nutrients are introduced

Statements by Head researcher Adam Perriman:

- Designing the Bio Ink was extremely challenging

- We required a material to be printable and maintain its shape when immersed in nutrients

- Newly designed Bio ink should not harmful to the cells

- The Bio Ink components were extracted from a retrofitted 3D printer and transformed to a gel at 37 degree celcius

Benefits:

- Help printing complex tissues using the patient’s own stem cells for surgical bone or cartilage implants

- Used in Knee and hip surgeries

- Enable to differentiate the stem cells into osteoblasts to engineer 3D printed tissue structures

- This created microscopic pores in the structure which provided more effective nutrient access for the stem cells

University of Bristol:

Red brick research university located in Bristol, United Kingdom

AffairsCloud Recommends Oliveboard Mock Test

AffairsCloud Ebook - Support Us to Grow

Govt Jobs by Category

Bank Jobs Notification