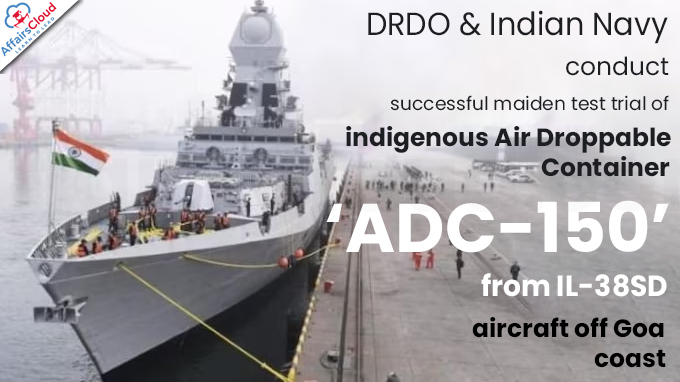

The Defence Research & Development Organisation (DRDO) and Indian Navy (IN) conducted the successful maiden test trial of ‘ADC-150’ from IL 38SD aircraft off the coast of Goa. It is an indigenously designed and developed Air Droppable Container with 150 kg payload capacity.

Developers:

It is developed by 3 DRDO laboratories viz. Naval Science & Technological Laboratory (NSTL), Visakhapatnam (Andhra Pradesh); Aerial Delivery Research & Development Establishment (ADRDE), Agra (Uttar Pradesh) and Aeronautical Development Establishment (ADE), Bengaluru (Karnataka).

- The flight clearance certification was given by Regional Center for Military Airworthiness (RCMA), Kanpur, UP headed by Centre for Military Airworthiness & Certification (CEMILAC), Bengaluru.

Reason behind this development:

To enhance the naval operational logistics capabilities by providing quick response to meet the requirement of critical engineering stores to ships (under distress), which are deployed more than 2,000 kms from the coast.

DRDO conducts Design Validation Trial of Vertical Shaft based Underground Ammunition Storage Structure

The Design Validation Trial Vertical Shaft based Underground Ammunition Storage Facility was conducted successfully by detonating 5,000 kgs of Trinitrotoluene (TNT) in one of the chambers of the underground facility.

- This facility was designed and developed by the Centre of Fire, Explosive and Environment Safety (CFEES), a Delhi-based laboratory of DRDO.

Benefit:

This facility will ensure that an explosion within will not cause damage to the adjacent chamber and also ensure full operability of the remaining facility, as, it enables upward vertical dissipation of blast effects.

Reason:

The Armed Forces face challenges in storing ammunition due to the lack of enough land. To store ammunition, safety distances need to be maintained, which is hard when there’s limited space. But underground storage can reduce safety distances, as seen in trials. Using a new design, they’ve found that 120 metric tons of ammunition per chamber can be safely stored with a lower safety distance. This design is also 50% cheaper and safer from attacks or sabotage.

Recent Related News:

i.Murugappa Group-owned Carborundum Universal Limited (CUMI) has signed a Licensing Agreement for the Transfer of Technology (LAToT) with DRDO’s Research Centre Imarat (RCI) Laboratory for licensing technology to manufacture “Ceramic Radomes (GELCAST Process) Technology” used in missile systems.

ii.On March 14, 2023, DRDO conducted two consecutive successful flight tests of Very Short Range Air Defence System (VSHORADS) missile at the Integrated Test Range (ITR), Chandipur, Odisha.

About Defence Research & Development Organisation (DRDO):

Chairman– Dr Samir V Kamat

Headquarter– New Delhi, Delhi

Establishment– 1958